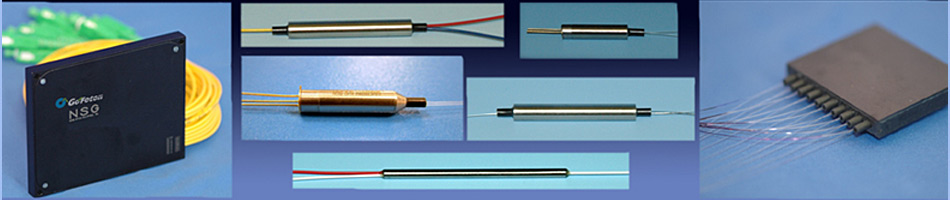

Unidirectional Tap Detector Array,

4, 8 and 10 Channels

Applications: Applications:

-

EDFA Power Monitoring/Control

- DWDM Channel Monitoring

- ROADM Port Monitoring/Control

Features:

-

Low Ripple

- Low Insertion Loss

-

Extremely Low Dark Current

- Epoxy-Free Dark Current

- Excellent Directivity Performance

Description:

Go!Foton’s integrated Unidirectional Tap Detector is now available in a 4ch, 8ch, or 10ch array package. Go!Foton’s Unidirectional Tap Detector combines 3 important optical functions in to a single package: an optical tap based on Go!Foton’s filter on lens technology, an isolator function achieved through Go!Foton’s proprietary packaging technique, and a PIN photodiode based on Go!Foton’s proprietary InGaAs fabrication process. The hermetically sealed InGaAs photo detector has a low dark current, a flat and rapid power response and extremely high temperature stability across a wide wavelength range. Go!Foton’s filter on lens allows customers to choose tap proportion as well as wavelength range so that monitoring can be achieved on a single wavelength or a broad spectrum. Now these industry leading performance components are available in Array type packages to support densely packaged multi-channel power monitoring applications. Fewer component parts result in greater space efficiency, ease of handling, and inherently higher reliability.

Dimensions:

Specifications:

The products supplied to this specification shall meet or exceed all the requirements specified here in.

| A. Absolute Maximum Rating |

|

|

|

|

|

|

|

|

|

|

|

| Parameter |

Symbol |

Unit |

Specification |

| Min. |

Typ. |

Max. |

| Operating Temperature |

Top |

°C |

-40 |

- |

+85 |

| Operating humidity Range (No Condensation) |

RHOP |

% |

5 |

- |

95 |

| Storage Temperature Range |

Tstg |

°C |

-40 |

- |

+85 |

| Storage Humidity Range (No Condensation) |

RHstg |

% |

5 |

- |

95 |

| Reverse Bias |

Vr |

V |

- |

- |

25 |

| Forward Current |

If |

mA |

- |

- |

10 |

| Electrostatic Discharge(ESD) Threshold C:100pF,R:1.5kΩ,Human Body Model |

VESD |

V |

200 |

- |

- |

| Soldering Temperature (< 10 sec) atleast 2mm away from the device’s body. |

TSol |

°C |

- |

250 |

- |

| B. Optical & Electrical Characteristics |

|

|

|

|

|

|

|

|

|

|

|

|

| Parameter |

Symbol |

Unit |

Specification |

Condition |

| Tap Ratio |

TR |

% |

0.5 |

1 |

2 |

5 |

10 |

30 |

50 |

|

| Wavelength Range |

λR |

nm |

1520~1570 |

C-Band |

| 1570~1610 |

L-Band |

| 1510~1610 |

CL-Band |

| Insertion Loss |

IL |

dB |

<0.5 |

<0.5 |

<0.5 |

<0.6 |

<0.8 |

<2.3 |

<3.6 |

λR , Top |

| Wavelength Flatness |

WDL |

dB |

<0.1 |

C-Band and L-Band |

| <0.15 |

CL-Band |

| Temperature Dependent Loss |

TDL |

dB |

<0.15 |

1550nm , Top |

| Polarization Dependent Loss |

PDL |

dB |

<0.05 |

1550nm,RT |

| Return Loss |

RL |

dB |

>50 |

1550nm,RT |

| Minimum Responsivity |

RsMIN |

mA/W |

4 |

8 |

16 |

45 |

70 |

240 |

350 |

λR , Top, Vr:5V |

| Maximum Responsivity |

RsMAX |

mA/W |

8.5 |

15 |

26 |

65 |

145 |

400 |

600 |

λR , Top, Vr:5V |

Wavelength

Dependent Responsivity |

WDRs |

dB |

<0.4 |

C-Band , Top, Vr:5V |

| <0.4 |

L-Band , Top, Vr:5V |

| <0.45 |

CL-Band , Top, Vr:5V |

| Maximum Optical Power Handling |

Pmax |

dBm |

26 |

23 |

20 |

16 |

13 |

8 |

6 |

|

| Temperature Dependent Responsivity |

TDRs |

dB |

<0.4 |

C-Band , Top, Vr:5V |

| <0.4 |

L-Band , Top, Vr:5V |

| <0.45 |

CL-Band , Top, Vr:5V |

| Polarization Dependent Responsivity |

PDRs |

dB |

<0.2 |

λR , Top, Vr:5V |

| Directivity |

Dir |

dB |

>25 |

TAPD-UC Model |

| >33 |

TAPD-UCP Model |

| Dark Current @ 25°C |

IdRT |

nA |

<0.08 |

Vr:5V |

| Dark Current @ 85°C |

IdHT |

nA |

<2 |

Vr:5V |

| Linearity |

LIN |

% |

±5% |

PIN: +10dBm to-30dBm, Vr:5V,1550nm,RT |

| Capacitance |

C |

pF |

1.3(maximum) |

1MHz, Vr:5V |

| Bandwidth |

BW |

GHz |

2.5 (Typical) |

-3dB,RL=50Ω,Vr:5V |

Qualification and Reliability

Opto-Electronic devices has been qualified according to Telcordia GR-468, CORE “Generic Reliability Assurance Requirements for Opto-Electronic Devices used in Telecommunications Equipment” and the applicable company Product Quality and Reliability Program that includes conduct of Telcordia GR-468 section 2.1.4 Requalification and On-going Reliability Test (ORT) requirements and/or its equivalent.Any change to identified test conditions requires justification and approval and shall be communicated to Customers.

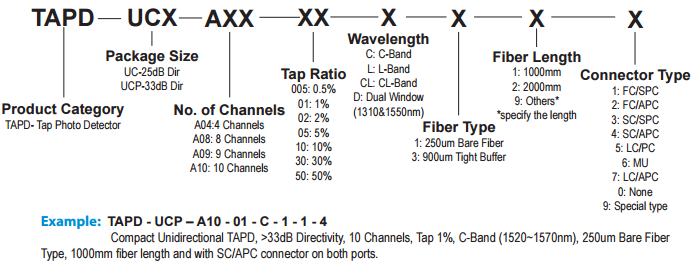

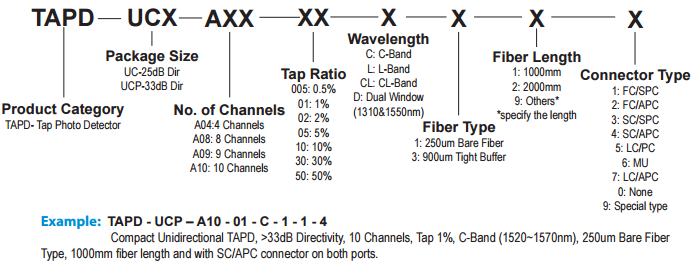

Ordering Information:

PDF data sheet PDF data sheet

|

Applications:

Applications: